Hydraulic systems, as a critical power source in modern industries, agriculture, and construction machinery, have their stability and reliability directly impacting equipment efficiency and safety. However, during long periods of high-intensity operation, hydraulic systems inevitably encounter common issues such as abnormal pressure, oil leakage, and delayed response.

In this article, Boxin Huasheng Hydraulics will provide a detailed analysis of common hydraulic system problems and troubleshooting methods, helping you efficiently identify issues, accurately pinpoint faults, and ensure stable equipment operation.

I. Identifying Common Failure Phenomena

The first step in troubleshooting is accurately identifying the symptoms. The following phenomena may indicate abnormalities in the hydraulic system:

Oil Leakage: Oil traces on the equipment casing, hoses, or joints.

Abnormal Noise: Whining or knocking sounds from the pump, valves, or oil lines.

Abnormal Movement: Hydraulic cylinders, motors, and other actuators respond slowly or unevenly.

Insufficient or Excessive Pressure: Abnormal fluctuations in system pressure.

Abnormal Control: Solenoid valves or proportional valves respond sluggishly.

Excessive Temperature: Abnormally high hydraulic oil temperature.

II. Hydraulic System Troubleshooting Steps

1. Check Hydraulic Oil Level and Condition

Ensure the oil is sufficient and the oil level is within the normal range.

Check if the oil quality has changed color, emulsified, or contains impurities; replace if necessary.

2. Check for System Leaks

Carefully inspect hoses, joints, and seals. If leaks are found, replace or tighten them promptly.

3. Measure Pressure

Use a pressure gauge to detect pressure in each circuit, determining if there are abnormalities with the pump, relief valve, or pressure reducing valve.

Adjust or replace faulty components according to design requirements.

4. Inspect Actuators

Check hydraulic cylinders and motors for sticking, internal leakage, or seal failure.

Ensure smooth movement of piston rods and sliding parts.

5. Check Valve Block Function

Determine if multi-way directional valves, relief valves, throttle valves, etc., are blocked or stuck.

Clean or replace internal contaminated components.

6. Check Pump Operation Status

Inspect hydraulic gear pumps and plunger pumps for idling, cavitation, or abnormal vibrations.

Repair or replace if necessary.

7. Check Electrical Control Section

Test solenoid valves, sensors, and control wiring for proper connections.

Test signal output to rule out circuit faults.

8. Clean Filters

Check if suction filters and return line filters are blocked.

Replace regularly to ensure clean oil.

9. Temperature and Cooling System Check

Excessively high oil temperatures can lead to decreased viscosity and reduced system efficiency.

Check if the cooler and water/air cooling systems are operating normally.

10. Check Seals

Regularly replace vulnerable parts such as sealing rings and O-rings to prevent leakage and cavitation.

11. System Flushing if Necessary*

Thoroughly flush severely contaminated systems to remove residual impurities from the oil lines.

III. Comprehensive Testing After Fault Repair

After troubleshooting and repairs are completed, it is recommended to perform functional tests under various operating conditions to ensure the hydraulic system returns to normal. Test items include:

Response speed of actions

Pressure stability

Oil temperature changes

Noise levels

IV. Establishing a Regular Maintenance Mechanism

Prevention is better than repair. It is recommended to establish a complete hydraulic system maintenance plan for your equipment, including:

Regular replacement of hydraulic oil and filters

Regular tightening of joints

Regular detection of pressure and flow

Regular cleaning of valve blocks and oil lines

V. Boxin Huasheng Hydraulics Provides One-Stop Solutions

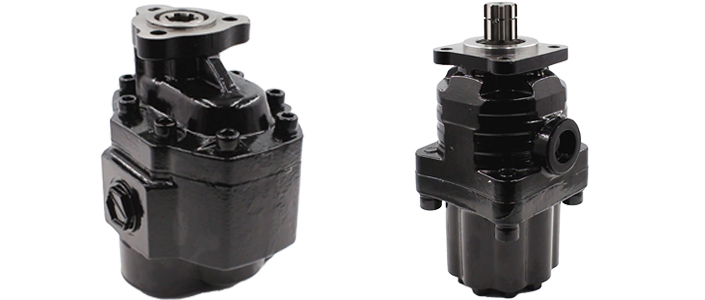

As a professional hydraulic system manufacturer, Boxin Huasheng Hydraulics not only provides you with high-quality hydraulic valves, hydraulic pumps, hydraulic motors, and steering units but also offers comprehensive technical support and system optimization services.

Whether for agricultural machinery, construction equipment, sanitation vehicles, mining machinery, or marine equipment, we can customize efficient and reliable hydraulic solutions for you.

For technical support or product inquiries, please feel free to contact Boxin Huasheng Hydraulic Technology Co., Ltd.